|

INTRODUCTION

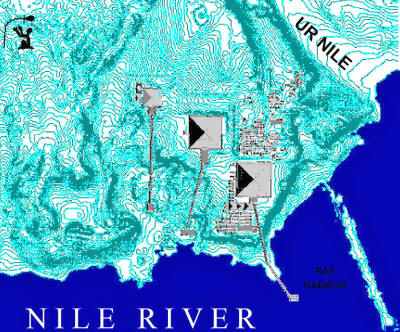

FIGURE 1. Giza

Plateau Layout

(Left) The causeway from the Great

Pyramid can be seen leading down to the location of the ancient Nile

River. The causeway was a hollow structure nearly half a mile long.

Why did they need this hollow structure? (Right) The retaining wall

is an accepted part of the pyramid structure. This retaining wall

would have been as high as the entrance door. What did it need to

retain?

Did these buildings actually come from

an earlier time of a more advanced civilization?

Many mathematicians embrace the building. They show that it incorporates numerous advanced mathematical relations within its design:

Many architects marvel at the size and precision of the building:

The Mystery schools (Masons,

Rosicruscians, Templars, etc.) view the building as a sonic

initiation machine that leads to higher knowledge.7 The Masons put

the Great Pyramid on the back of the U.S. one dollar bill.

FIGURE 2. Giza

Plateau Topographical

The Nile River was a major factor for

the Giza plateau design. Just as important as the Nile was the

Western Nile (Ur Nile). The Western Nile was at a higher elevation

and gravity fed many miles of underground aqueducts3 . One function

of the aqueducts was to provide water to the Great Pyramid’s moat.

Water escapes from the waste valve until the water‘s velocity forces the valve shut. When the valve shuts, the water stops flowing instantaneously and causes the water to compress resulting in a compression wave, or shock wave, to emanate from the valve area. In the drive line, the water reverses direction until the shock wave reaches air and returns down the pipe.

In the output line, a high pressure

surge passes through the check valve. This surge is at least fifty

times (3,360 psi at Giza) the static water pressure of the

compression chamber. When the compression wave leaves the

compression chamber, a low pressure situation exists. The low

pressure is equal and opposite to the compression wave. This

immediately re-opens the waste valve. The stand pipe is a shortcut

for the compression wave to reach air. Once the compression wave

reaches air, a wave returns down the stand pipe and starts the water

flow back into the compression chamber. The stand pipe, usually

twice the diameter of the drive pipe, allows for the highest

possible cycling rate.

FIGURE 3. Standard

Hydraulic Ram Pump The basic hydraulic ram pump has water running from the elevated water source to the compression chamber. A valve in the compression chamber allows water to flow out until the velocity forces the valve shut. The valve shutting causes a high pressure spike that forces water past the check valve and through the output line. The waste valve reopens and once again allows water to flow down the pipe. The stand pipe affects the cycle rate by creating a shortcut for the reverse surge.

FIGURE 4. Specialized

Application Hydraulic Ram Pump Building an underground ram pump requires lengthening of the compression chamber to allow for waste water output. The output line is placed on the ceiling of the compression chamber to automatically remove air from the chamber. The line from the waste valve to compression chamber acts as a wave guide, effectively focusing the shock wave into a pulse. This pulse impacts the compression chamber’s ceiling effectively transmitting part of the pulse vertically and reflecting part of the pulse back down the waste valve line. Design: John Cadman

FIGURE 5. Confirmed

Existence at Giza

Before theorizing about missing parts,

it is important to view what is known to have existed. Although the

retaining wall (1) no longer is in existence, it is an accepted part

of the complex. The retaining walls and casing stones were

dismantled for building materials.

On top of the step are two fins that run

from the front of the step to the back wall. A third fin starts ½

way back on the step. All of the fins run east to west and reach up

near the ceiling. On the main floor there is a {6’} wide square pit

set diagonally some 5’ from the eastern wall. This pit drops 5 ½‘ to

a step where the pit narrows to 4’ square. The total depth of the

pit is about 11’ although Cavigula had drilled down another 30’ in

the 1800’s.5 In the southeastern corner is the entrance to a tunnel

that measures 29” by 31”. Dubbed the ”dead end” shaft, this tunnel

runs 57’ due south where it ends in a vertical wall.

Parr recognized that it was the location of a sound transmission that energized the pyramid.

FIGURE 6. Views of

the Subterranean Chamber It is difficult to describe the largest room of the Great Pyramid. Upon entering the room we are faced with a pit tunneled in the middle of the floor. One half of the room is a large step with odd fins. The handrail around the pit was added in modern times to prevent visitors from falling into it. Photos: Guardian’s Giza, Edgar Brothers, GPG-RA

FIGURE 7. The

Subterranean Chamber Layout Although these drawings were a primary source for the models, they have errors in the finned area and the pit’s relative angle. The fin errors were a result of the fins being filled with rubble. The pit is also rotated slightly from it’s diagonal offset. The bottom drawing shows the location of the small recess that corresponds to the best location for an air or gas removal line.

The blocked line leads up into the pyramid with the

best output being the Queen’s chamber niche.

As the moat filled, water flooded the entrance and ran down the descending passage (3) into the subterranean chamber (6).

FIGURE 8. The Basic

Passage Layout The pump assembly incorporates the descending passage (3), subterranean chamber (6), the “dead end” shaft (7), the pit (8), the well shaft (4) and grotto (5). To complete the basic hydraulic ram, two blocked tunnels need to be cleared. At the end of the “dead end” shaft exists a plane surface that correlates to the backside of a check-valve. The pit hasn’t been completely cleared of rubble to expose the horizontal shaft, yet. In the running model the water in the well shaft pulsed at the grotto height even though this is below moat elevation.

This tunnel was a drain that

had a mechanical element at its end. This mechanical element is

possibly a sliding stone plug, which opened and closed causing a

pulsing action (see Figure 24). The “dead end” shaft (7) terminates

57’ past it’s entrance. It is my hypothesis that the termination is

the back face of a closed check valve, and a tunnel exists beyond

(see inset Figure 8).

The excess water was removed by the causeway

running down to the Nile River (see Figure 1).

A model was built

drawing upon the Edgar brothers’ sketches8 (see Figure 7), Flinders Petries’ dimesions9, Edward Kunkel’s drawings1, and every photograph

I could find. Photographs played a crucial part in verifying details

on various drawings. A 1:48 scale was decided upon. This scale

utilizes ¾”, 1” and 1 ¼” pipes. The subterranean chamber is 8” x 13”

x 5”. By August of 1999 I had built a model as described by Kunkel.

The first model leaked, cracked and, worst of all, didn’t run.

Four months passed and then in the last hours of the millennium (New Year’s Eve 1999), I had a vision of the correct layout. With renewed excitement, model construction continued (see Figure 10).

Within four months (April 3, 2000) I had constructed a working model that started running on the first try! (see Figure 11)

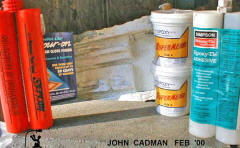

FIGURE 9. Model No. 3

Casting and Ceiling Installation (Left) The model has been removed from the rubber mold, and it is ready for entrance and exit fittings. (Right) The ceiling block has been sealed by saturating it with clear epoxy resin. The model is then glued to the block with the a slightly pliable epoxy to absorb shock without cracking. The whole model is then covered with a mix of the two epoxies, fiberglass, and steel reinforcements.

Corporate sponsorship would be welcomed . . . “The epoxy that built the pyramid”

FIGURE 10. The Model

Preparing for Cement The model before cement was added. The pit shaft was angled west then south in this model for strength. At Giza the shaft goes due southeast. The model uses twin 45’s instead of single 90’s to mimic the 45 degree reflective elbow of Giza. (Right) The horizontal passage into the subterranean chamber model utilizes square interior to mimic the tunnel at Giza.

FIGURE 11. The First

Working Model - April 3, 2000 (Left) Originally believing that water was pumped to the King’s chamber, the model is shown pumping to that elevation. (Center) A barrel was used for the reservoir, but filling limitations forced moving the model to a seasonal creek with a pond utilized for the reservoir. (Right) The model is housed within reinforced cement, while at Giza, the subterranean chamber is housed under 100 feet of bedrock.

In either case, the room is situated to withstand shockwaves.

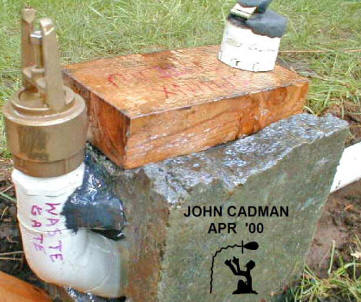

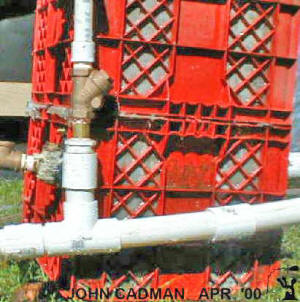

FIGURE 12. The

Wastegate and the Bypass (Left) The original wastegate was vertical with a variable weight utilized to reopen the valve. Later, the valve became horizontal with no weight, utilizing only the rarefaction wave to reopen valve. The vortex of the subterranean chamber would spin the valve 30’ down the line. (Right) To compare the pumping unit with the subterranean chamber in place versus without, a straight pipe was fit in place where the room would have been. This resulted in a much simpler assembly that still pumped. There were two main differences. There was a large reverse pulse at the reservoir and the output flow was more erratic.

This

demonstrated how the subterranean chamber absorbed much of the

reverse pulse. |