|

by Brian Berletic

September 25, 2014

from

Bioitmag Website

The first 3D printer to reach Earth's orbit was launched this

week aboard

SpaceX's Dragon cargo ship.

Destined for the International Space

Station (ISS), the 3D printer (designed

by 'Made in Space') will allow astronauts to experiment with

fabrication in orbit. While the 3D printer will be limited in terms

of materials and the size of the objects it can print, and with its

prints of limited utility to astronauts, it is still a crucial first

step on a road toward immense implications.

Below are 3 of these implications.

1. Objects on Demand

Until now, any object or tool

required on space missions either had to be rigged from existing

objects on hand or launched into orbit.

Rigging objects is a solution of last resort, something that

Apollo 13 astronauts were famously required to do in order to

save their ill-fated mission to the moon.

Launching objects into

orbit is a costly and time-consuming proposition. But with a 3D printer, this is no

longer a problem.

As long as input material is on hand, any

object astronauts are capable of designing or have on digital

file, can be fabricated on demand, aboard the space station.

Made in Space is currently working

on a system that will recycle spent input material making it

possible to print out and reprint designs perpetually.

Made in Space's 3D printer is shown here

being tested via

microgravity parabolas,

essentially when

an airplane nose-dives at a specific rate

to simulate zero

gravity in Earth's orbit.

For carefully planned missions on

the ISS and with regular resupply missions able to provide

astronauts with everything they could possibly need, this is not

so much an issue.

However, on longer missions, to say

the Moon or Mars where mission parameters may be unpredictable

and resupply missions are out of the question, the ability to

fabricate replacement parts, tools, and other objects can make

all the difference.

2. "Teleporting" Objects

Because a 3D printer works by taking

a digital file and converting it into layers of printed

material, astronauts on space missions could use files from

three possible sources.

-

They could design the object

themselves with 3D design software.

-

They could pull it from a

library of objects on their hard drive.

-

Or third and more

interestingly, they could have it sent to them from

Earth where engineers could design, modify, and

re-modify any idea they can imagine.

Instead of sending a physical

article to the astronauts which may not even be possible, they

can instead send the digital file via communication signals at

the speed of light.

Once received, the 3D printer can

begin printing, resulting in an object designed on Earth,

fabricated and placed in the hands of astronauts hundreds of

thousands of miles away.

3. Large Scale Construction

One of the biggest limitations on

what we can build in space is the amount of material we can

launch into orbit from which to build.

What if instead, fabrication tools

like 3D printers could be launched and with a limited amount of

material, fabricate larger tools to begin heavy construction in

orbit. Asteroids and other sources of material already beyond

Earth's gravity could be utilized to construct everything from

spacecraft to orbital colonies.

Amid this process, smaller

Earth-launched fabrication systems could scale themselves up in

both numbers and size to meet any demand.

Plausibility?

The first two implications should be self-evident.

We already have a 3D printer in orbit

now that soon will be printing objects on demand. In addition to

tests run by mission control and astronauts, design contests among

students on Earth are ongoing and finalists will send their ideas

via data-link to the ISS to be printed out aboard.

In essence, students will "teleport"

their designs to astronauts with the final product printed out in

orbit and placed in the hands of the ISS' crew.

The third implication may still be a

ways off, but several private space firms are already researching

just how to use fabrication techniques like 3D printing and the

knowledge gained from Made in Space's printer to build everything

from

a lunar base to a floating space colony "spun" from captured

asteroids.

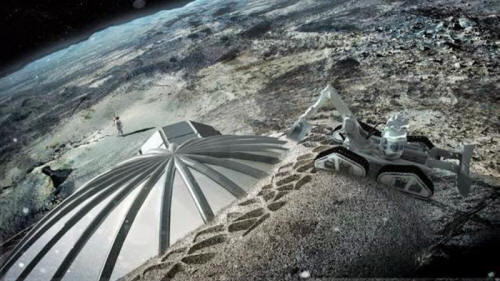

Renowned architectural firm

Foster + Partners for example,

has teamed up with the ESA to see

how feasible 3D printing is with lunar soil.

The concept they developed includes an

inflatable bladder that forms a dome upon which 3D printed material

is deposited before hardening and providing a protective covering

for the structure.

There are already large-scale

architectural 3D printers on Earth and coupled with lessons learned

from Made in Space's 3D printer now in orbit,

devising ways of

printing architecture beyond Earth's gravity is

the next logical step.

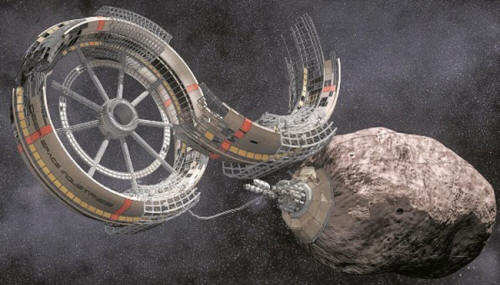

Deep Space Industries (DSI) is already developing a fleet of

autonomous and remotely operated spacecraft to search out and

explore asteroids for their potential mining and use as building

materials.

During DSI's initial public roll out,

concept art depicted a torus-shaped space habitat (known as a

Stanford torus) being "spun" out of an asteroid.

While the concept art doesn't specify

what means of fabrication the space habitat was being "spun" with,

DSI has stated that it too

is preparing

to use 3D printing as a means of large-scale fabrication in

space for both parts and whole objects, and out of a variety of

materials including metals

While the initial prints aboard the ISS may not be overly

impressive, the launch of Made in Space's 3D printer into Earth's

orbit and its use is a necessary first step on a much larger and awe

inspiring journey.

Just as the Wright Brothers' first

flying machine was considered a novelty of little use, so too may

the first 3D printer in space. But just like the Wright Brothers'

first flying machine, the first 3D printer in space carries with it

immense, potentially paradigm-shifting implications.

The former ushered in the dawn of an age

of human flight, the latter may usher in

the permanent settlement of humanity amongst the stars.

|