|

April 05, 2013

from

RT

Website

Spanish version

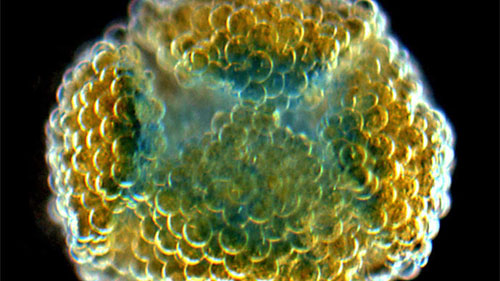

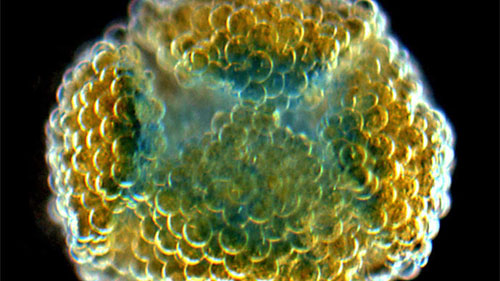

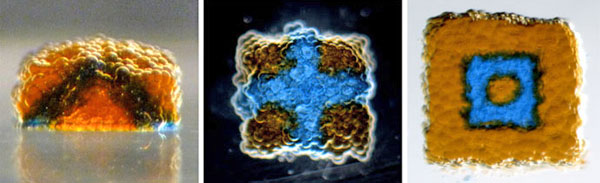

Droplet

network that self-folded

into hollow ball

c.400 microns across

(credit: Oxford

University / G Villar)

Researches have built a new type of 3D printer that creates

tissue-like material that could revolutionize medicine.

The artificial material produces the

properties of living tissues and could potentially replace them in

the future. The new material developed by scientists at Oxford

University consists of water, coated and protected by lipid

molecules.

The tens of thousands of 3D connected

caviar-like droplets were named 'droplet networks'.

“We add chemicals and bio chemicals.

This changes the water. After all we humans are made of networks

of water droplets” Professor Hagan Bayley of Oxford University's

Department of Chemistry commented, as cited by the Daily Mail.

The 'droplet networks' could one day

replace damaged living tissue or deliver drugs to specific

locations, the researchers said in a study released Friday in

Science magazine.

"We aren't trying to make materials

that faithfully resemble tissues but rather structures that can

carry out the functions of tissues," said Professor Bayley in a

news briefing on the Oxford university website.

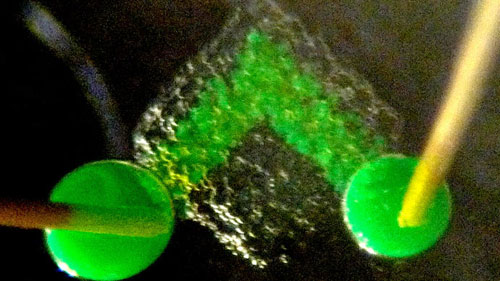

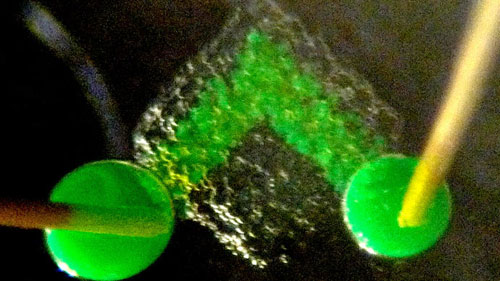

Droplet network c.500

microns across

with electrically

conductive pathway

between electrodes

mimicking nerve

(credit: Oxford

University / G Villar)

"The droplets can be printed with

protein pores to form pathways through the network that mimic

nerves and are able to transmit electrical signals from one side

of a network to the other," he added.

Eventually this material could replace

the use of stem cells, a completely synthetic material, has no

genome and does not replicate. The creation of 'droplet networks'

avoids many problems such as harvesting living tissue.

The Oxford scientists said that there was no printer to build these

aqueous droplets as so far they have developed 3D printers that can

only create solid objects. So they found a way out by building one

in their laboratory.

The unique 3D printer was built by

Gabriel Villar, a student and the lead author of the paper.

"Conventional 3D printers aren't up

to the job of creating these droplet networks, so we custom

built one in our Oxford lab to do it," said Professor Bayley.

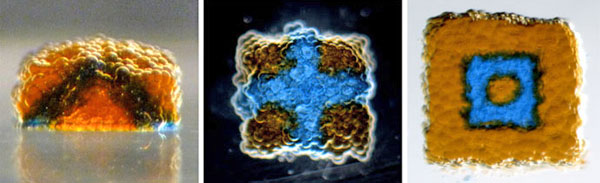

Printed droplet

networks c.500 microns across

(Credit: Oxford

University / A Graham)

Each droplet is 50 microns in diameter, about 0.05 millimeters, but

it is five times larger than a living cell.

Professor Hagan Bayley said that

given more time and funding they will be able to develop smaller

networks.

"At the moment we've created

networks of up to 35,000 droplets but the size of network we can

make is really only limited by time and money. For our

experiments we used two different types of droplet, but there's

no reason why you couldn't use 50 or more different kinds."

At present the material remains stable

for weeks.

This synthetic material can be designed to take on different shapes

after it was printed. This resembles muscle movement. The

researchers have demonstrated the through the creation of a

flowerlike droplet network that from the initial flat shape curls

into a sphere.

The movement is triggered by a process called osmosis.

The droplets on the bottom of the network are filled with a high

concentrated solution, and the ones on the top are filled with a low

concentration. After the droplets are printed the solvent molecules

on top flow into the droplets on the bottom through a partially

permeable membrane.

When that happens the droplets on top

shrink and the droplets on the bottom blow up causing the whole

structure to curl.

3D printing gives vast opportunities such as to create objects as

complex as human organs.

There are certain advantages of using

artificial tissue in comparison with living tissue, says Cameron

Ferris a research associate from the ARC Centre of Excellence

for Electromaterials Science at the University of Wollongong,

ABC Science reports.

He is part of a team that develops 3D

printers to potentially create replacement organs using living

cells.

"It's incredibly expensive to

harvest stem cells [for 3D printing of living tissue], and the

food you have to feed them, to grow and expand them so that you

have enough stem cells to print takes some time” he said,

according to ABC science.

Hear, hear!...

Scientists Create Human-Like Ears

...with 3D

Printing

February 21, 2013

from

RT

Website

Spanish version

Larry Bonassar,

Cornell Associate

Professor of Mechanical Engineering.

(AFP Photo / Lyndsay

France)

The latest innovation in 3D printing -

artificial ears - feel, look and behave identically to human ones.

The new product developed in the US could provide patients who are

missing all or just part of their ear with a chance at

reconstructive surgery.

Cornell biomedical engineers and Weill Cornell Medical College

physicians published their study online in the PLOS ONE journal on

Wednesday.

They show how they developed an ear over the course of three months

by inserting living cells into an injection mold and then growing

cartilage in the shape of its mold.

"This is such a win-win for both

medicine and basic science, demonstrating what we can achieve

when we work together," co-lead author Lawrence Bonassar,

associate professor of biomedical engineering at Cornell, told

AP.

According to the study, the first

implant could be tried in around three years.

A 3-D printer.

(AFP Photo / Lyndsey

France)

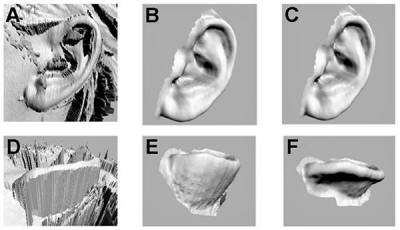

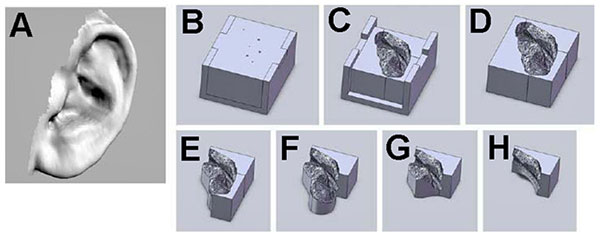

Researchers began the project by creating a digitized 3D image of a

human ear, which was used to build an ear-shaped mold using a 3D

printer.

Then they injected a gel made of living cow ear cells and collagen

(a substance used to make gelatin) into the mold and the ear was

done.

The production part took less than two days: only half a day to

build the mold, a day to print it, 30 minutes to insert the gel,

then wait 15 minutes and everything was ready to go.

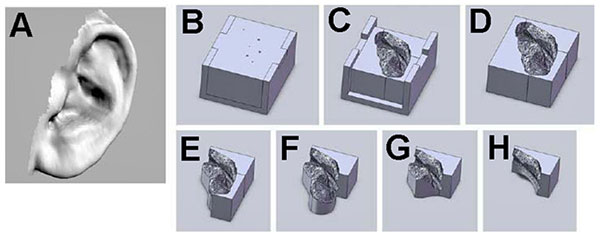

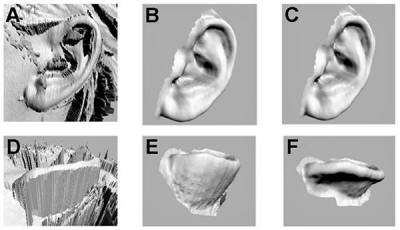

Digitization process for human ears.

(Image from

plosone.org)

Scientists tested the artificial ears by implanting them on the

backs of rats and it took one to three months for the ears to grow.

Rodents are often used by scientists to test the growing of

artificial ears.

"We trim the ear and then let it

culture for several days in nourishing cell culture media before

it is implanted," Bonassar told AP.

The need for the product is there.

Thousands of children who are born with ear deformities and those

who have lost an ear during their life could benefit from the new

technology.

The most common deformity is microtia, when the external ear does

not fully develop. In US one to four children per 10,000 are born

with it, according to the study.

People born with microtia usually have an inner part of the ear

fully functional, but they still have impaired hearing because they

are missing part of their external ear.

Mold design

based on ear anatomy.

(Image from

plosone.org) )

"A bioengineered ear replacement

like this would also help individuals who have lost part or all

of their external ear in an accident or from cancer," co-lead

author Jason Spector told Live Science.

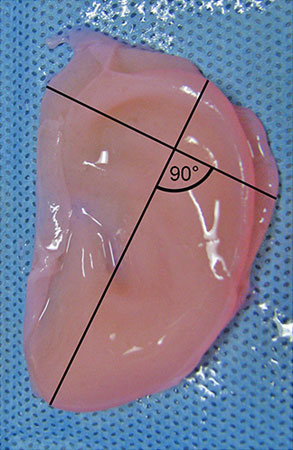

Researchers identified the best time for

implantation for the kids to be at around the age of five or six,

when the ears are at 80 per cent of their adult size.

The study says that a chance of rejection during implant procedure

could be potentially decreased by using human cells from the same

patient when constructing the bioengineered ear.

Before this point, technology only allowed to build replacement ears

with a foam-like consistency or by using a patient's harvest rib,

the latter is a painful process and ears still often looked

unnatural and did not properly work.

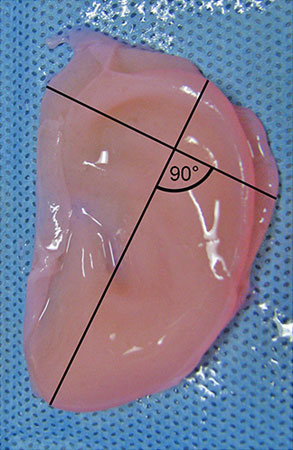

Schematic

representation of length and width measurements.

(Image from

plosone.org)

A Tissue-Like Printed Material

April 2013

from

2n2n

Website

Spanish version

British researchers said in

a report published in the journal

"Science", they use a special 3D printer to print out material

similar to the biological tissue, this outcome expected future

applications in the medical field.

This report is published jointly by Professor Hagan Bayley of

the University of Oxford and colleagues.

According to reports, they take

advantage of the the 3D printer hierarchical profuse droplets of

lipid film wrapped, these droplets form a mesh structure, constitute

a special new material.

The researchers say, to print out the material texture with brain

and adipose tissue similar folding action can make a similar

muscle-like activities, with work like neurons as the communication

network structure can be used to repair or enhance the failure of

the organ. Synthetic materials, it also avoids the problems caused

by some the way manufacturing living tissue with stem cells.

The researchers also said that conventional 3D printers can not

print this new material, experiment, they used a special 3D printer,

this printer ejected droplet diameter of approximately 50 microns, 5

living cells so but I believe will be able to reduce the size of the

droplets.

In recent years, 3D printing technology rapid development, from

engineering to aerospace, from education to health care, application

more widely.

In February of this year, Cornell

University researchers had reported that,

"They use cells from ears

of cattle on 3Dprinters to print out the artificial ear."

A Tissue-Like Printed

Material

by Gabriel Villar,

Alexander D. Graham, Hagan Bayley

Science 5 April 2013:

Vol. 340 no. 6128 pp. 48-52

DOI: 10.1126/science.1229495

Living cells communicate and cooperate to produce the emergent

properties of tissues.

Synthetic mimics of cells, such as

liposomes, are typically incapable of cooperation and therefore

cannot readily display sophisticated collective behavior. We

printed tens of thousands of picoliter aqueous droplets that

become joined by single lipid bilayers to form a cohesive

material with cooperating compartments.

Three-dimensional structures can be

built with heterologous droplets in software-defined

arrangements.

The droplet networks can be

functionalized with membrane proteins; for example, to allow

rapid electrical communication along a specific path. The

networks can also be programmed by osmolarity gradients to fold

into otherwise unattainable designed structures.

Printed droplet networks might be

interfaced with tissues, used as tissue engineering substrates,

or developed as mimics of living tissue.

Read the full report: "A

Tissue-Like Printed Material".

|