|

by Michael Berger

August 23,

2021

from

NanoWerk Website

|

This

article is a few years old, but is a good primer about

Smart Dust.

The

technology and the industry forming around it is huge

and totally transformative.

Of

course, should not be surprising that DARPA started this

in the first place, for military applications on the

battlefield.

Then, Technocrat scientists took it from there.

Source |

Imagine a cloud of sensors, each the size of a grain of sand or even

smaller, blown aloft by hurricane winds and relaying data on the

storm to weather stations below.

Picture an,

invisible sensor

network embedded into a smart city's roads to monitor traffic,

road surface damage and identify available parking spaces - all

in real time.

Or billions of

nanosensors distributed over forests and other areas with fire

hazards to detect a fire at its very beginning.

Or envision

programmable smart dust that triggers an alarm signal when

invisible microcracks are detected in a turbine blade.

Smart dust refers to

wireless networks of sub-millimeter-scale autonomous computing and

sensing platforms not larger than a grain of sand.

Smart dust senses and

records data about its environment such as light, temperature,

sound, presence of toxins or vibrations, and transmits that data

wirelessly to larger computer systems.

Smart dust is a vision of the networked future where intelligent

networks of trillions of miniscule sensors continuously feel,

taste, smell, see, and hear what is going on in their

surrounding environment, communicate with each other and

exchange information.

Smart dust networks

are the ultimate Internet-of-Things (IoT) devices.

Smart dust is revolutionary because the sensors are small enough

to be put anywhere, even in narrow and difficult areas.

Another huge advantage is

that these devices work without any human intervention as they are

pre-programmed and, notwithstanding their tiny size, have their own

power supply.

This technology is expected to not only monitor,

-

building controls

-

pipelines

-

factory equipment

-

drug-making

processes,

...but it will also lead

to ubiquitous autonomous artificial intelligent computation near the

end user, such as,

Although smart dust

devices are not quite in dust-size territory, researchers hope to

shrink these devices to the size of a speck of dust via

nanotechnology.

To be economically feasible, such single-use devices have to be

cheap (we are talking pennies or even fractions of a penny), even

cheaper than the radio-frequency identification tags currently used

to track the inventory of warehouses, for example.

How does smart

dust work and what does it do?

Smart dust networks contain nodes (called 'mote') that combine

sensing, computing, wireless communication capabilities and

autonomous power supply in a tiny package with a volume of few cubic

millimeters or even less.

Smart dust is based on microelectromechanical systems, or MEMS. MEMS

consist of any combination of mechanical (levers, springs,

membranes, etc.) and electrical (resistors, capacitors, inductors,

etc.) components to work as sensors or actuators.

In the future, as

fabrication technologies advance, this will shrink further down in

size to NEMS - nanoelectromechanical systems.

Motes are constructed using conventional silicon microfabrication

techniques and can remain suspended in an environment similar to

dust (hence the name).

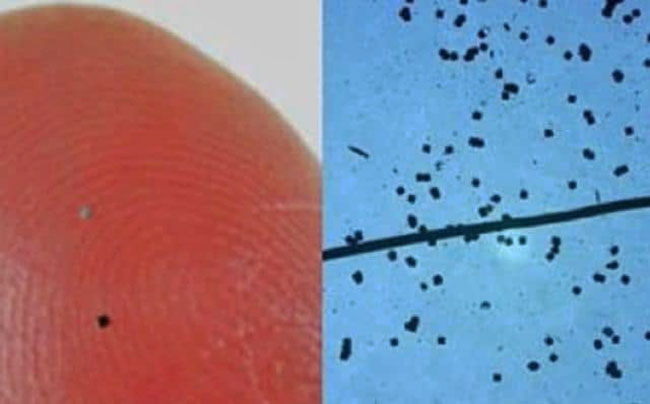

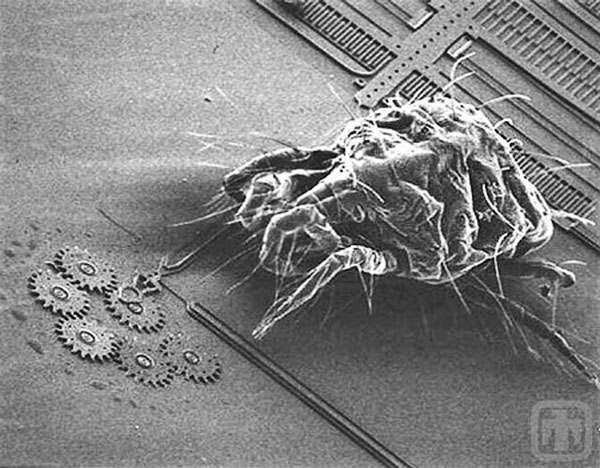

A mite, less than 1 mm in size,

approaching a microscale gear chain.

(Image:

Sandia National Laboratories)

Each mote can be left unattended to collect environmental data such

as light, temperature, pressure, vibrations, the existence of

toxins, etc., and transmit this data wirelessly to larger, remote

computer systems - or, depending on the mote's computing power,

processes it directly at the point of data collection.

For instance,

in an industrial

setting, smart dust sensors relay signals back to a command

computer, which then compiles the data to give feedback to plant

managers.

Or the results could

trigger an automatic response, such as turning down a building's

temperature or reducing the flow of water.

Another example is

DARPA's SHIELD program that plans

to use microscale chips to track and authenticate the supply chain

of computer chips for defense applications.

The goal is to eliminate

counterfeit integrated circuits from the electronics supply chain by

making counterfeiting too complex and time-consuming to be cost

effective.

SHIELD aims to combine

NSA-level encryption, sensors, near-field power and communications

into a tiny chip capable of being inserted into the packaging of an

integrated circuit.

Origin of the

smart dust concept

'Smart Dust' was first conceived in the 1990s by Dr. Kris Pister

while a professor of electrical engineering at the University of

California, Berkeley, as a simple way to deploy intelligent wireless

sensors.

At the time, Pister imagined a world in which ubiquitous sensors

could measure everything that could be measured.

Immediately, he thought

about environmental applications such as weather tracking (read his

concept paper from 2000:

Emerging challenges: Mobile networking for

"Smart Dust").

But it doesn't come as a surprise that it was the military that gave

the impetus, and financing, for developing smart dust.

In 1992, DARPA funded

Pister's research in the Smart Dust project (you can read the

original proposal

here as PDF).

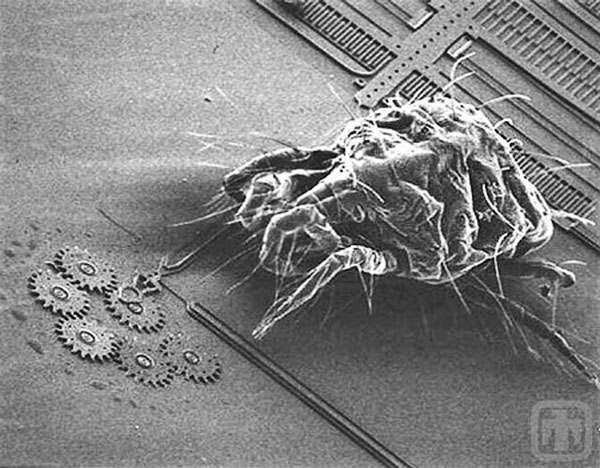

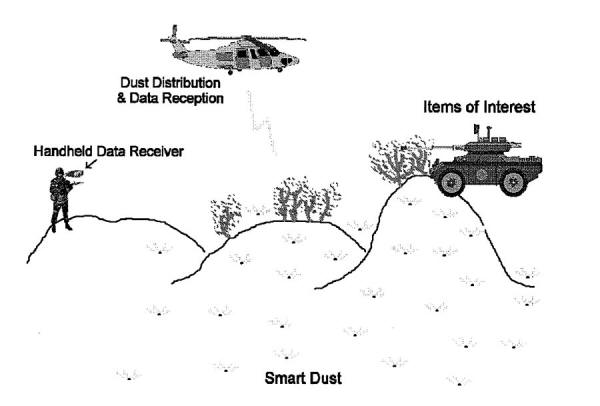

Schematic of a smart dust battlefield sensor network

as depicted in the grant application

for

DARPA's Smart Dust project:

Thousands of sensor nodes covering square kilometers

are delivered by autonomous helicopter.

They track motion of vehicles for hours/days,

and report information superimposed on live video

when interrogated by hand-held receiver

or helicopter-borne receiver.

Components of

a smart dust mote

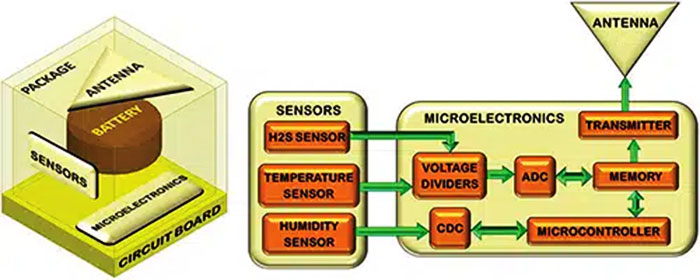

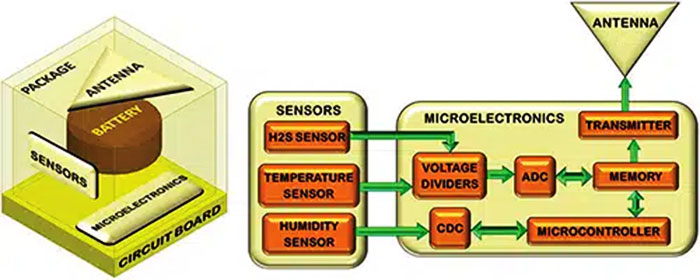

Very basically, every mote consists of four device classes: sensors,

circuits, communication, and power supply.

In a wireless sensor node

this would conceptually look like this schematic:

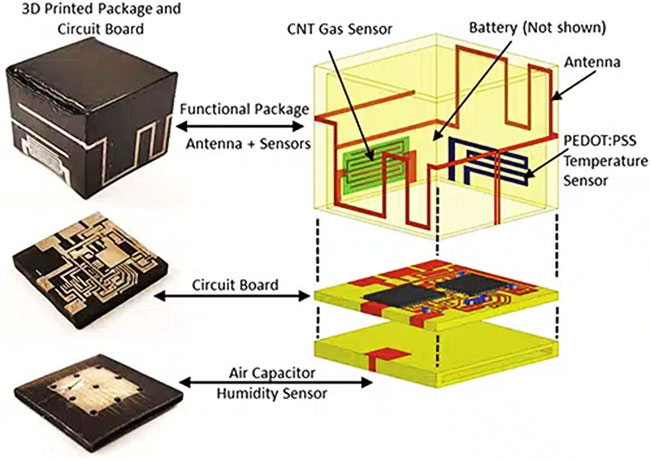

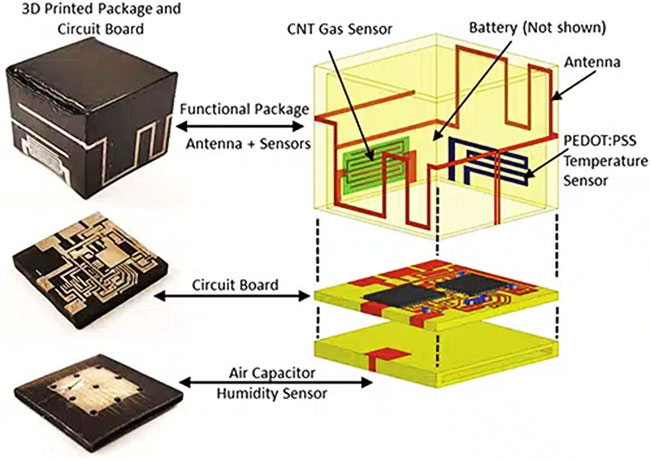

Example for the system design of a wireless sensor node.

It

consists of a 3D-printed functional cube package

which

contains several inkjet-printed sensors and the antenna.

The

circuit board has also been 3D-printed

and

contains the microelectronics enclosed in the package.

(Source: DOI 10.1002/admt.201700051)

The entire package contains one or more MEMS or NEMS sensors to

perform the mote's principal sensing purpose of detecting and

measuring things like,

-

vibration

-

temperature

-

pressure

-

sound

-

light

-

magnetic field,

etc.

Circuits

(microcontroller) to interface with the sensors and process and

store data.

Communication ideally

comprises a transmitter and 3D antenna which ensures equal radiation

in all directions, thus enabling orientation insensitive

communication.

Power supply for the

entire mote, depending on the area of operation, could be a solar

cell array or some form of thin-film battery or supercapacitor.

The whole package looks like this:

Read more about this 3D-printed,

fully integrated wireless sensor device.

Although the cube dimensions in above example are 21 mm on each

side, it illustrates the basic concept and component architecture of

a smart dust mote.

Inevitable

miniaturization will ultimately lead to sub-micron scale for these

devices.

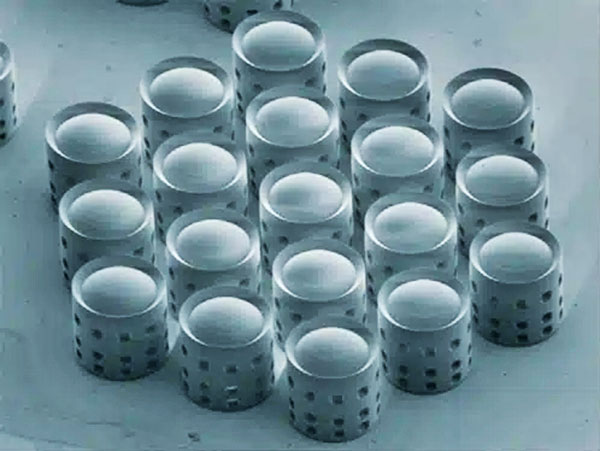

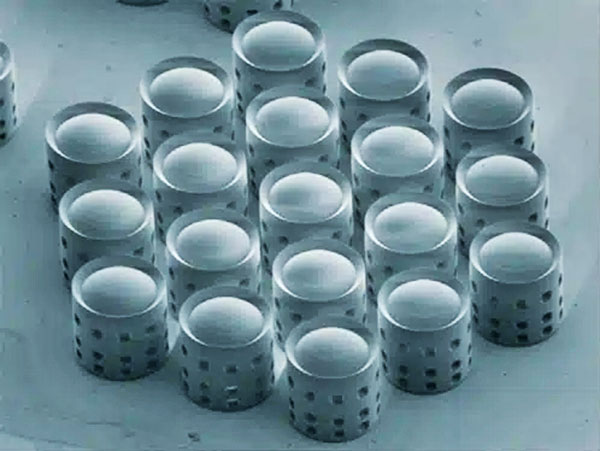

Here are two more examples of how miniaturization leads to

incredibly tiny components.

Scanning electron microscope image

of

the hexagonal lens arrangement.

Each

doublet lens system has a

diameter of 120 µm and a height of 128 µm.

Scale

bar, 100 µm.

(Source: DOI 10.1038/NPHOTON.2016.121)

Researchers have demonstrated fully working multi-lens objectives

with sizes of around 100 microns, roughly the size of a grain of

salt, that could lead to smart dust motes with autonomous vision.

The lenses show

unprecedented performances and high optical quality with resolutions

of up to 500 line pairs per millimeter for imaging applications.

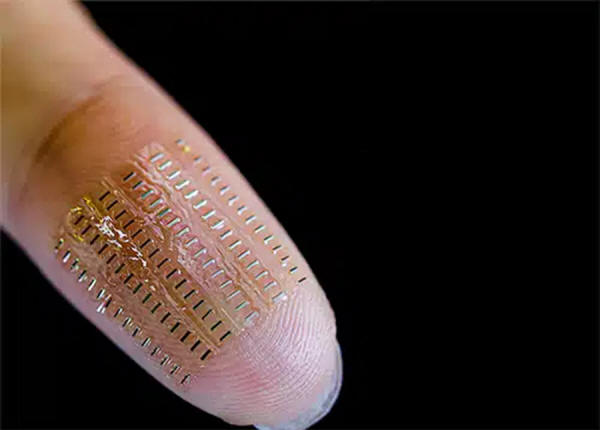

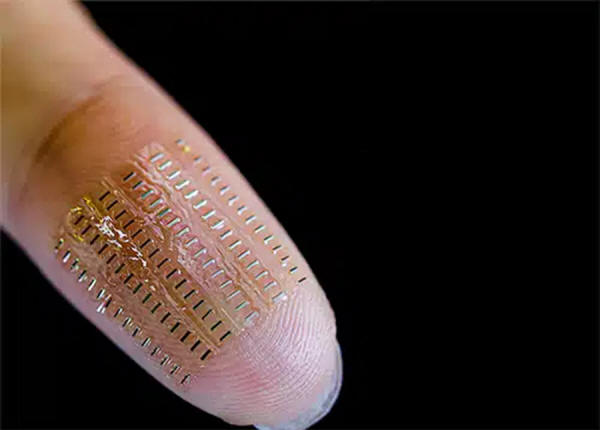

Dust-sized

power supply

Ever smaller energy storage devices in the submillimeter range for

even smaller microelectronic components are a major technical

challenge.

Nevertheless, researchers

manage to continuously reduce their size, as this example of a

nanosupercapacitor shows - it is

the size of a speck of dust but packs the voltage of an AAA battery:

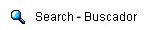

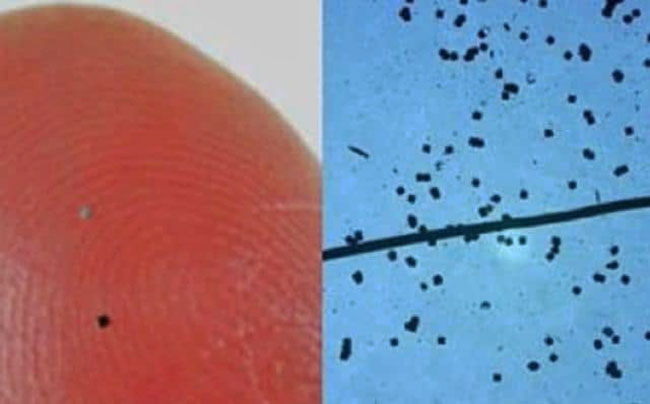

Each of the 90 tubular supercapacitors on the fingertip

holds a

volume of just 1 nanoliter (0.001 mm3)

but

delivers up to 1.6 V supply voltage.

Neural smart

dust

Granted, this application is a bit further out, but actively worked

on by researchers.

And, again, the military

is spearheading this through DARPA's

Electrical Prescriptions (ElectRx) program.

Researchers have developed a safe, millimeter-scale wireless device

small enough to be implanted in individual nerves, capable of

detecting electrical activity of nerves and muscles deep within the

body, and that uses ultrasound for power coupling and communication.

They call these devices

neural dust.

Each neural dust sensor consists of only three main parts:

a pair of electrodes

to measure nerve signals, a custom transistor to amplify the

signal, and a piezoelectric crystal that serves the dual purpose

of converting the mechanical power of externally generated

ultrasound waves into electrical power and communicating the

recorded nerve activity.

And while not networked

yet, researchers already demonstrated the feasibility of inserting

computer chips into individual cells.

But you can imagine where

this could go...

Current status

and challenges

The main challenges researchers have been grappling with are the

lack of enough power on the small footprint and the difficulties of

integrating power systems into these highly scaled devices.

Since the storage density

of battery technologies has not followed Moore's law scaling trends,

IoT systems need to rely on power conversion from outside sources

such as thermal, vibrational, light, or radio waves.

As nanoelectronics and packaging technologies evolve, though, now

may be the right time that we start to rethink the solutions for

these problems and advance towards more powerful small computer

systems than what was originally proposed.

The ability to integrate various nanoelectronic chiplets - such as

processor, memory, and photovoltaics - in an industrial-scale

wafer-level-packaging process, creating solar-powered smart dust,

unlocks the potential of large-scale manufacturing of these compact

integrated systems with high performance and ultralow cost.

Applications

of smart dust

The vast range of smart dust application makes it impossible to

provide detailed descriptions in just a single article.

So we just list some

major areas below:

-

Agriculture

Constant

monitoring of a crop's nutritional requirements, watering,

fertilization, and pest control. This valuable information

can help to increase the quantity and quality of the crop.

It can also

record soil conditions such as pH, fertility, microbial

infestations, i.e., information vital for the plant's

growth.

-

Industries:

Continuous

screening of essential equipment, prompting action regarding

its maintenance. Assessing the exact condition of machines,

their weakness, and corrosion can prevent complete system

failure.

-

Environment:

Chemical and

biological environmental monitoring for health and safety

issues (water, air, soil). For instance,

plasmonic smart dust could

probe local chemical reactions as shown in this animation:

Animation of the hydrogen dissociation

and uptake on a palladium surface.

The smart dust (a silica shell-isolated gold nanoparticle)

reports changes in the local chemical environment

via spectral shifts in its scattering spectrum.

(Source: Sven Hein, 4th Physics Institute,

University of Stuttgart)

-

Urban infrastructure:

Monitoring for

buildings, roads, bridges, tunnels, water and sewer pipes,

electrical and telecommunications grids will become part of

an overall concept of

a smart city.

For instance,

smart dust could already be embedded into concrete during

construction.

-

Inventory management:

Tracking products

from their manufacturing factories to retail shelves via

transport facility (ship vessels to trucks) would ensure

tight inventory control.

-

Medical

diagnostics:

see neural smart dust above

-

Transport sector:

Smart dust

transports perishable goods as these materials require

constant monitoring.

While

transporting perishable goods, certain parameters such as

temperature, humidity, and aeration have to be monitored

continuously.

Similarly, smart

dust helps to monitor animals' health and control the

necessary conditions such as temperature, air, and humidity

for safe transport.

-

Military applications:

It helps in

accessing activities in remote or inaccessible areas.

It can also

determine the presence of toxic gases or harmful substances

and help take necessary actions. Battlefield sensor

networks.

-

Space exploration:

Weather,

seismological monitoring on planets and moons in the solar

system.

Scientists are

also exploring an entirely new type of space telescope with

an aperture made of swarms of particles released from a

canister and controlled by a laser.

NASA's Innovative

Advanced Concepts Program is funding the second phase of the

"orbiting rainbows" project that attempts to combine space

optics and smartdust, or autonomous robotic system

technology.

Smart dust

risks and concerns

Wide-scale adoption of smart dust would bring with it a number of

risks:

-

Privacy

Many that have

reservations about the real-world implications of smart dust

are concerned about privacy issues.

Smart dust

devices will become so small that they are invisible to our

naked eye and, therefore, are extremely difficult to detect.

They can be

programmed to record whatever their sensors are capable of

(ironically, people have begun to voluntarily carry devices

that would accomplish exactly that).

You probably

won't know who is collecting the data and what they are

doing with it.

Your imagination

can run wild regarding the negative privacy implications

when smart dust falls into the wrong hands

-

Control

Once billions of

smart dust devices are deployed over an area it would be

difficult to retrieve or capture them if necessary.

Given how small

they are, it would be challenging to detect them if you

weren't made aware of their presence.

The volume of

smart dust that could be engaged by a rogue individual,

company or government to do harm would make it challenging

for the authorities to control if necessary.

-

Cost

As with any new

technology, the cost to implement a smart dust system that

includes the satellites and other elements required for full

implementation is high.

Until costs come

down, it will be technology out of reach for many.

-

Pollution

Smart dust motes

essentially are single-use devices. Unless they are fully

biodegradable the question arises if they will pollute the

areas where they are used (soil, air, water).

-

Health

As soon as smart

dust particles shrink to the nanoscale, their risk profile

will match that of nanoparticles in general and the

potential health risk associated with inhaling or ingesting

them.

-

Legal issues

The lack of

security protecting information created by smart dust

networks is creating not only privacy concerns, but the

network can be accessed without authorization (i.e., hacked)

by third parties and its information can be used for illegal

purposes.

Video

|