|

from

BigThink Website (UNIVERSITY OF MANCHESTER)

Graphene is absolutely amazing stuff, the lightest, strongest stuff we know of.

According to the University of Manchester:

Scientists the world over are envisioning uses for the one-carbon atom thick, essentially two-dimensional allotrope, including:

And now, a team of scientists at University of Manchester have developed a solution to one of our most serious and vexing problems:

It could lead to a way, as Science Alert puts it,

The United Nations says that 1.2 billion people currently live in areas with insufficient drinkable water.

Graphene was first produced in 2004 when two scientists at The University of Manchester, Andre Geim and Kostya Novoselov stripped away layers of graphite one at a time using Scotch tape (!) until only a single layer, graphene, remained.

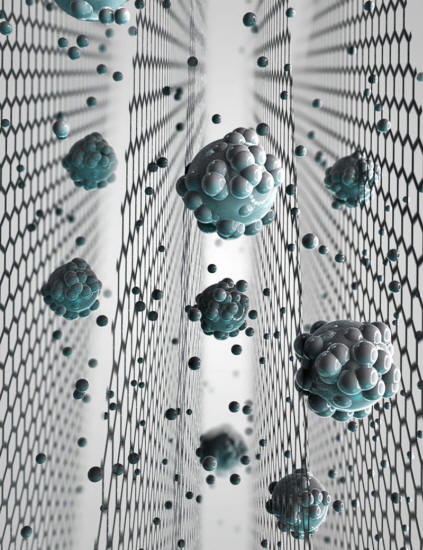

The new technique uses a new graphene-oxide membrane as a sieve that filters out salt molecules from water.

Graphene membrane (UNIVERSITY OF MANCHESTER)

The idea of using graphene-oxide membranes for desalinization isn't new - their atom-scale pores are perfect for the job - but this is the first successful attempt to make it happen.

When previous membranes were immersed in water, they'd absorb it, swelling up and enlarging the pores, ruining their ability to catch tiny salt molecules.

The University of Manchester's team, led by Rahul Nair, has solved this problem by building walls of epoxy resin around the membrane to keep its atoms dry when underwater.

Now that they have that issue resolved (Tunable Sieving of Ions using Graphene Oxide Membranes), as Nair told Phys.org,

While still in the experimentation stage, Nair says his team's results bode well for manufacturing membranes large enough to be deployed on a large scale.

As exciting a solution as this may prove to be for generating drinkable water, the team says water's just the beginning when it comes to purpose-built sieves using graphene.

|