|

November 04, 2010

from

NextBigFuture Website

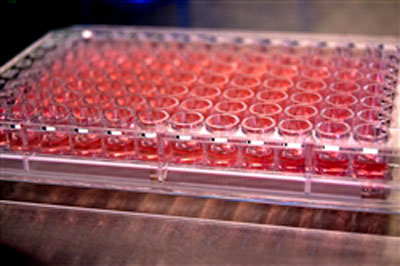

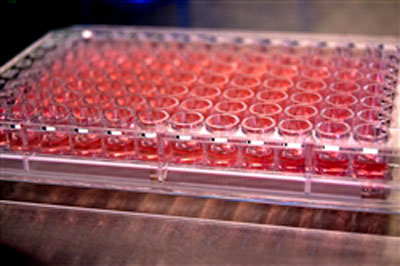

Each well in the

MIMIC system’s 96-well plastic plate represents a human immune

system.

The MIMIC system's

highly sensitive functional assays simulate a clinical trial

for a diverse

population without ever putting human subjects at risk.

Photo by Todd Lemoine,

courtesy of VaxDesign

A

DARPA effort, called Blue Angel,

has been working since May 2009 to develop a surge capacity for flu

viruses.

Eighteen months and $100 million later,

Blue Angel and the companies it funds have created new technologies

for developing, testing and quickly mass-producing new vaccines.

-

The DOD/Darpa progress on

tobacco plant production (with several companies) of vaccine

is progressing to industrialization to ramp up production of

a seed vaccine instead of using chicken eggs.

-

Speeding phase 3 testing and

lowering costs - Now, pharmaceutical company with a

candidate vaccine needs to enroll 10,000 people for three

years and $100 million. An alternative may be

MIMIC, a DARPA technology

developed by Florida-based biotechnology company VaxDesign

Corp. $1 million and 2 months to predicts the vaccine to

produce for humans.

-

Venter working on synthetic

biology for 12 hour identification and production of seed

vaccine.

-

DNA vaccine technology also

being developed in separate projects. Success could scale up

the seed vaccine in 12 hours to fully produce the vaccine

doses in one day.

For the largest program, called AMP for

Accelerated Manufacture of Pharmaceuticals, companies in four states

are building facilities where they can quickly produce vaccine-grade

proteins grown in the cells of tobacco plants.

Once they produce the proteins, the goal

is for each company to scale up its process to produce 100 million

doses of H1N1 flu vaccine per month. Existing vaccine manufacturers

worldwide produce a fraction of that - about 300 million doses of

vaccine in six months, Magill said.

Craig Venter

had indicated that synthetic

biology can produce the seed stock for a vaccine in 12 hours. It

would need to be used in conjunction with DNA vaccine technology to

achieve one day vaccine production.

Gutmann asked Venter whether, by next flu season, we could,

"have a one-day production, through

synthetic biology, of a flu vaccine?"

To which he answered that researchers

could produce the seed stock for the vaccine in just 12 hours.

Venter added that with,

"rapid DNA sequencing, we can

predict, we think, well in advance what the changes will be for

next year's flu before the WHO even makes the decision as to the

vaccine stocks."

Production, he said, is a whole

different story entirely.

Prather agreed.

"If you're still making [a vaccine]

in chicken eggs, it's not going to happen in a day. It's just

not going to happen," she said.

"So, there's a difference between

the tools of synthetic biology being able to give you what that

starting material is, if we're stuck with chicken eggs it's not

going to happen, if you go to chicken cell culture, it's going

to be faster, if the DNA vaccine technology proves out and you

can do it in microbes, you can absolutely do it in a day."

This, she was quick to point out, is an

immunological issue, not a synthetic biology problem.

Vaccines are produced in steps, beginning with getting a sample of

the active virus. From the original virus, “seeds” are used to grow

the virus in hundreds of millions of chicken eggs - a time-consuming

process developed more than 50 years ago. After the virus particles

are grown, they’re purified to make vaccine.

AMP set out to speed up the process by looking at a range of animals

and plants whose cells could produce high-quality proteins that

would work well in people, Magill said.

What emerged from the first round of

experiments were tobacco plants.

“Think about walking through the

woods on a rainy day. You walk through on Tuesday and there’s

nothing there, and you take the same walk on Wednesday and

suddenly there’s a mushroom that’s a foot high and it grew

overnight,” Magill said.

“Anything in nature that produces a

tremendous amplification of biomass was of interest,” he added.

“Clearly these weeds - that’s really what tobacco plants are -

grow very fast, and that’s what we captured.”

Plants with the fastest-growing cells

will be able to produce more proteins in a shorter time for

vaccines, he explained.

Four companies are working to transform protein-producing tobacco

plants from a proof of concept to a demonstration of the capability.

The next step will be to develop full industrial processes for

producing the proteins.

The companies are,

-

Fraunhofer USA - Center for

Molecular Biotechnology in Delaware, Kentucky

-

Bioprocessing in Owensboro

-

A consortium called Project

GreenVax, whose partners are,

-

Texas A&M University system

-

a Texas company called G-Con

-

Medicago USA in North

Carolina

“They’re all using tobacco plants,

and there’s a little variation on the theme,” Magill said.

“But the approaches - what do you

put in the plants, how do you infect the plant cells, what kind

of vectors [carriers] do you use, what is the nature of the

protein, how is it purified - all of these are actually quite

different.”

The companies all are making progress,

he said.

One of them, Fraunhofer, already has a

product in Phase 1 clinical trials - the first stage of testing in

people.

“The final trial will go on for six

months, because we have to do safety monitoring,” Magill said.

“But we’ll know whether the technology worked probably about the

end of January.”

Another Blue Angel project is a

technology called Modular Immune In Vitro Constructs, or

MIMIC, which Magill calls “an

immune system in a test tube.” DARPA created MIMIC to quickly test

new vaccines for safety and effectiveness.

Pharmaceutical companies that produce candidate vaccines initially

don’t actually know if the drug will improve a person’s immunity or

will be safe when administered. That’s why in the United States the

Food and Drug Administration (FDA) requires companies to hold a series of

clinical trials before drugs are approved for market.

As a pharmaceutical company with a candidate vaccine, Magill said,

“all I can do is commit to a Phase 3

[effectiveness] study in which I will have to enroll 10,000

people over the course of about three years in order to… show

that my new vaccine in this case would be as good as the

traditional egg-based vaccine.

“So 10,000 people, three years, $100

million,” he said.

An alternative may be MIMIC, a DARPA

technology developed by Florida-based biotechnology company

VaxDesign Corp.

Each of MIMIC’s 128-by-85-millimeter plastic plates contains 96 tiny

wells filled with mixtures of human immune cells and biological

molecules. Each well represents a human immune system.

The system can predict the effectiveness of vaccine additives called

adjuvants and molecules that the immune system recognizes called

antigens, VaxDesign officials said, adding that it

can,

-

predict dosing, dose timing

and cross-protection against other viral strains

-

determine the potency of

stockpiled vaccines

-

compare the effects of different

manufacturing methods on vaccine potency

“It’s a very clever technology,”

Magill said. “I can look at the immune responses in the MIMIC

system and tell you that this is going to work, this is going to

protect patients, they’re not going to get sick and it’s going

to be really safe.”

In September, Sanofi Pasteur, the

vaccine division of the Lyon, France-based Sanofi-Aventis Group,

signed a binding agreement to buy VaxDesign for $60 million.

The full potential of MIMIC - to take the place of clinical trials -

could take years to realize.

But Magill said he has confidence in

the technology.

“Where this will be useful is in

what we call the down-select - when you’re in the business and

you’ve got five vaccine candidates and you’re not sure which one

is going to work,” he said.

Today, to down-select the best

candidate a company would have to do a year-long Phase 1 study

for each candidate that would cost $5 million to $7 million per

trial.

“But what if I can just replace all

that by going into MIMIC up front?” Magill said.

“Let’s say I spend $1 million in MIMIC, but I get the answer in

two months and that predicts the vaccine that I need to take

into humans,” he said.

“That’s huge. And I think the

likelihood of that occurring is pretty high.”

MIMIC will work in parallel with AMP to

test candidate H1N1 vaccines, Magill said, and both will complement

other projects that also are part of Blue Angel.

Technologies developed for Blue Angel eventually will apply to a

range of flu viruses and other diseases, Magill added.

“Blue Angel’s vaccine portfolio

alone has generated four facilities, four [technical]

approaches, two clinical trials, two [FDA investigational new

drug applications], the MIMIC and a variety of other spinoff

technologies,” he said, adding that it could take a decade to

commercialize the technology.

"Such an outcome for plant-based vaccines would be amazing," he

said.

“We don’t see very often that a response like this essentially

creates a new industry. But we’ll see,” Magill said.

“You still have to go through

clinical trials… and work through all the issues. But I would

say initially things are quite pleasing and somewhat promising.”

|